Classifications and application characteristics of cable mica tape

Synthetic mica tape

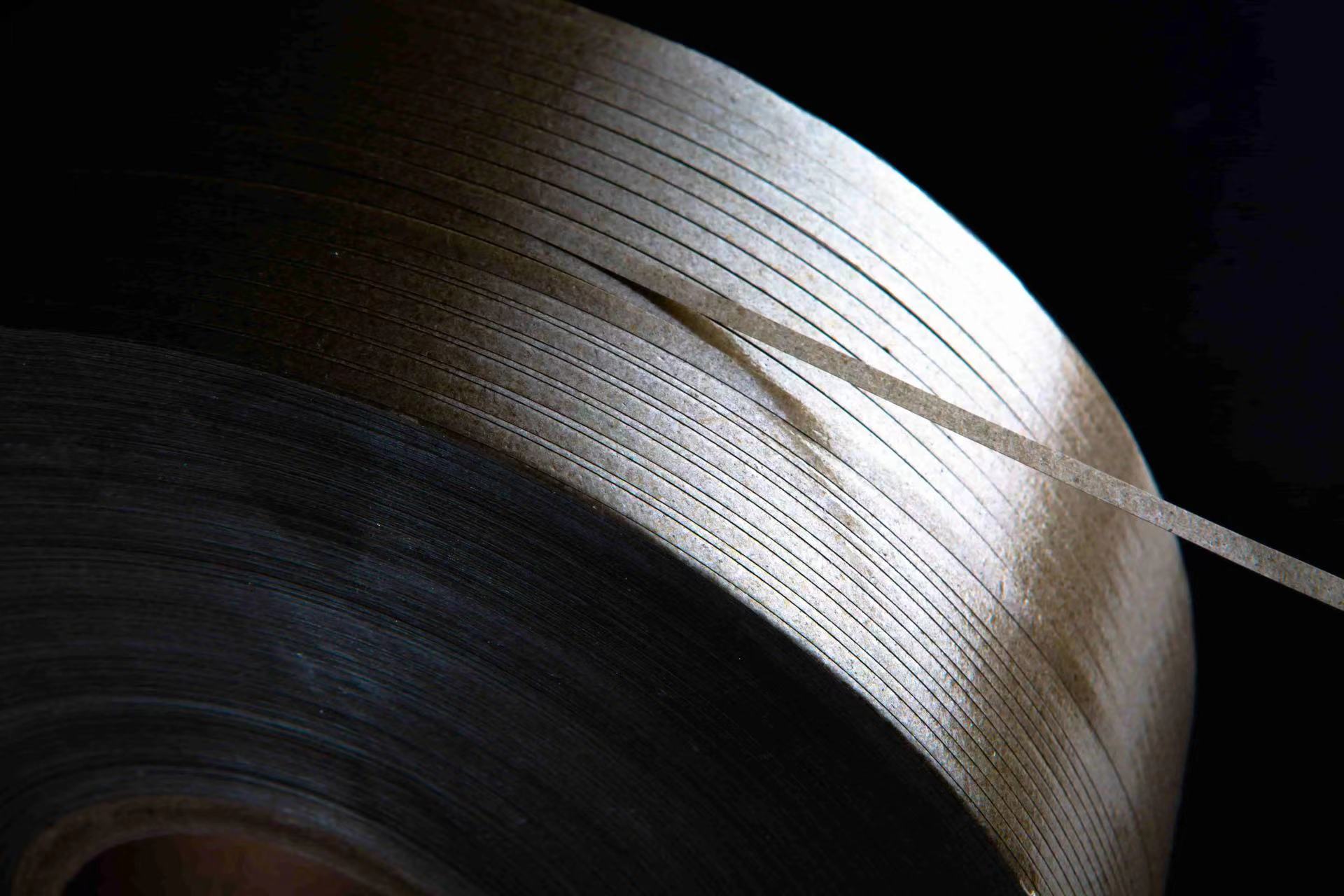

Synthetic mica is a kind of artificial mica with large size and complete crystal form, which is synthesized by replacing hydroxyl with fluoride ion under normal pressure. Synthetic mica paper, copied from synthetic mica, is the main material of synthetic mica tape, which is then attached to one or both sides of glass cloth with adhesive. During the manufacturing process, several structural layers are bonded together, then dried in the furnace, rolled up, and cut into belts of different specifications.

Synthetic mica tape has the characteristics of natural mica tape, such as small expansion coefficient, high dielectric strength, high resistivity, uniform dielectric constant, and its main feature is high temperature resistance, up to A-level fire resistance (950-1000℃).

The temperature resistance of synthetic mica tape is greater than 1000℃, with thickness ranging from 0.08 to 0.15 millimeters to 0.15 millimeters, and the maximum supply width is 920 millimeters.

Gold mica tape

Gold mica tape has good fire resistance, acid and alkali resistance, corona resistance, radiation resistance, softness and tensile strength, suitable for high-speed wrapping. Fire resistance test shows that the wire and cable wrapped with gold mica tape does not breakdown for 90 minutes at 840 and 1000 volts.

Gold mica glass fiber fire-resistant tape is widely used in high-rise buildings, underground railways, large power plants, and important industrial and mining enterprises related to fire safety and fire rescue, such as emergency power supply lines and control lines for emergency facilities such as fire equipment and emergency guidance lights. Because of its low price, it is the preferred fire-resistant cable.

Notes on wrapping cable mica tape

The process of wrapping cable mica tape is very important and must be highly valued and carefully operated. Here are some tips for wrapping cable mica tape:

- In the production of fire-resistant cables, wrapping technology is critical. The wire-winding machine can be divided into vertical and horizontal machines according to structure, and high-speed and low-speed wire-winding machines according to speed. However, the number of manufacturers specializing in mica tape-winding machines is scarce, and most of them are made using existing paper-winding machine and cable twisting machine heads.

- No matter what equipment is used, the operator must be serious and responsible. The operator should adjust and master the winding tension and winding angle according to the test results under the guidance of technical personnel, and not allow slipping or missing tapes. The surface of the insulated wire core after winding should be smooth and mica-free. Also, be careful to handle the joints to prepare for the next process.

- It should be noted that small wires are easier to cause mica to fall off due to their small curvature radius. Even if synthetic mica tape does not fall off, synthetic mica is more brittle than gold mica, which is prone to mica fracture, leading to unsatisfactory fire resistance performance of fire-resistant cables. Therefore, based on the characteristics of the manufacturer’s equipment and the test situation, each cable manufacturer should continuously explore experience, adjust and improve.

- Only by strictly controlling the wrapping process can the pass rate of finished products be greatly improved. Only by solving the wrapping problem, the influence of other processes on fire resistance is relatively small. The conductor wrapped with mica tape should be uniformly wound on the reel, paying attention not to scratch the mica layer, especially for large cross-sectional fire-resistant cables, avoiding the occurrence of events where two conductors rub each other and scratch the mica layer.