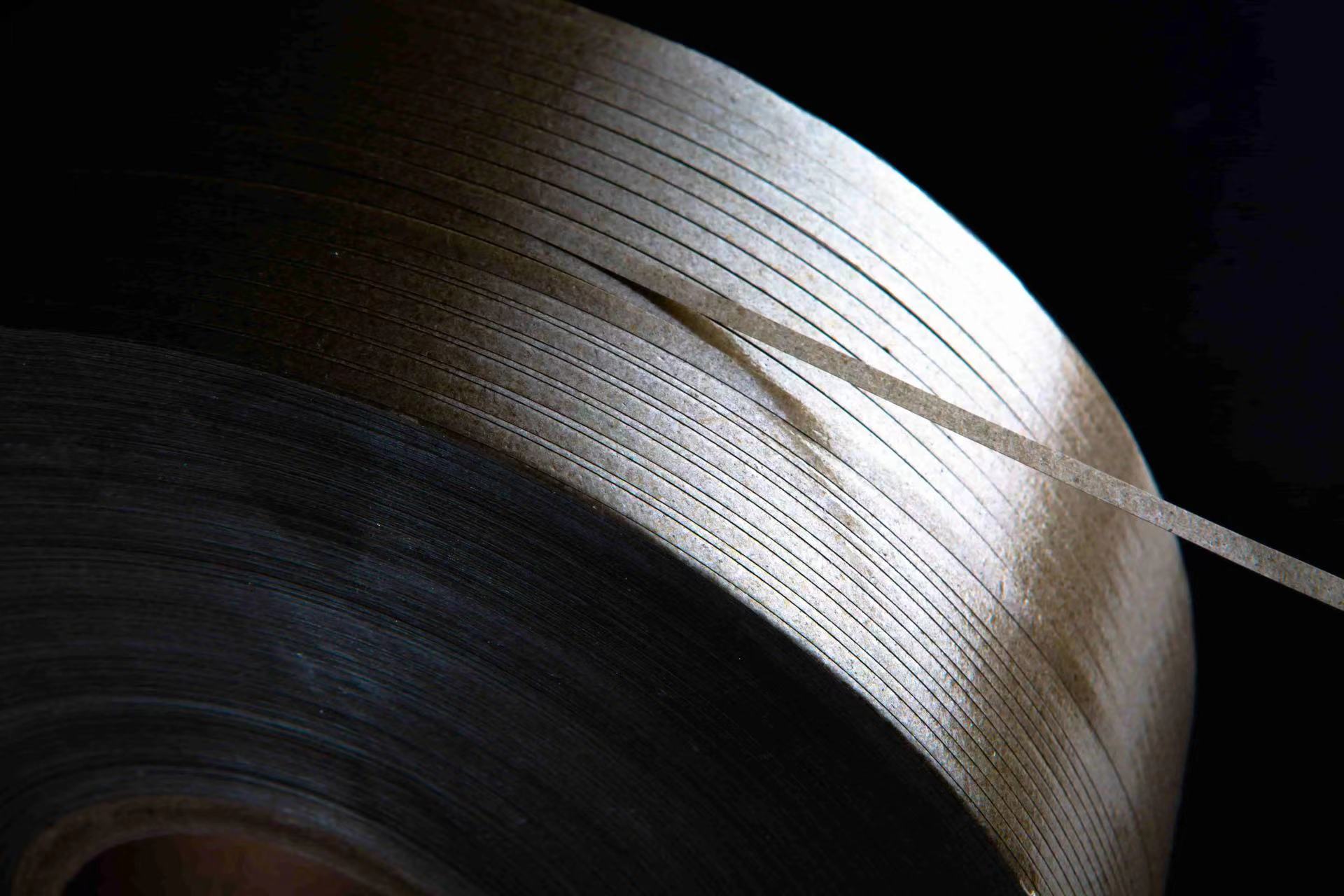

Electric cable mica tape is a high-performance mica insulation product with excellent high-temperature and flame retardant properties. Mica powder has good flexibility under normal conditions and is suitable for the main fire-resistant insulation layer of various fire-resistant cables. When burning in open flames, it hardly produces harmful smoke, making it not only effective but also safe for use in cables.

There are three types of mica tapes: synthetic mica tape, gold mica tape, and white mica tape. For small-sized cables, it is important to choose synthetic mica tape for wrapping. It is worth noting that mica tape cannot be layered and can easily absorb moisture if stored for a long time. Therefore, when storing mica tape, it is important to consider the temperature and humidity of the surrounding environment.

When using mica tape winding equipment for fire-resistant cables, good stability is required. The mica tape should be wrapped evenly and tightly, and all guiding wheels and guide rods in contact with the equipment must be smooth. The wiring should be neat, and the tension should not be too high. The side plate and barrel of the tensioning tool wheel should also be smooth.

For axially symmetric round-core mica tapes, they should be tightly wrapped in all directions. Therefore, the conductor structure of fire-resistant cables should adopt a circular compressed conductor. The reasons are as follows:

- Some users have suggested using bundled twisted soft-structured conductors, requiring companies to communicate with users from the reliability of cable use to circularly compressed conductors. Soft-structured bundles and multi-strand conductors can damage mica tape and are not suitable as conductors for fire-resistant cables. However, some manufacturers believe that they should meet the needs of users by providing the type of fire-resistant cables they require.

- Fan-shaped conductors are not suitable for use because the pressure distribution of the mica tape wrapping of the fan-shaped conductor is uneven, and the pressure is highest at the three fan-shaped angles of the wrapped mica tape.

Since mica is a layered silicate polymer, the interlayer molecular attractive force is much weaker than the covalent bonding force of the s1-0 bond in the crystal, and interlayer slippage and silicon adhesion are easy to occur. However, the adhesion strength is also low and it is easily detached and cracked when subjected to external scraping and squeezing forces. Especially when using a fan-shaped structure, the wrapped wire core is prone to be scratched and bumped when passing through the guiding wheel, branching rod, and wiring to reach the edge of the tool wheel side plate. During later processing, such as extrusion and insulation entering the mold core, the electrical performance may be reduced.

In addition, from a cost perspective, the cross-sectional circumference of a fan-shaped conductor structure is larger than that of a circular conductor, requiring an increase in mica tape material.