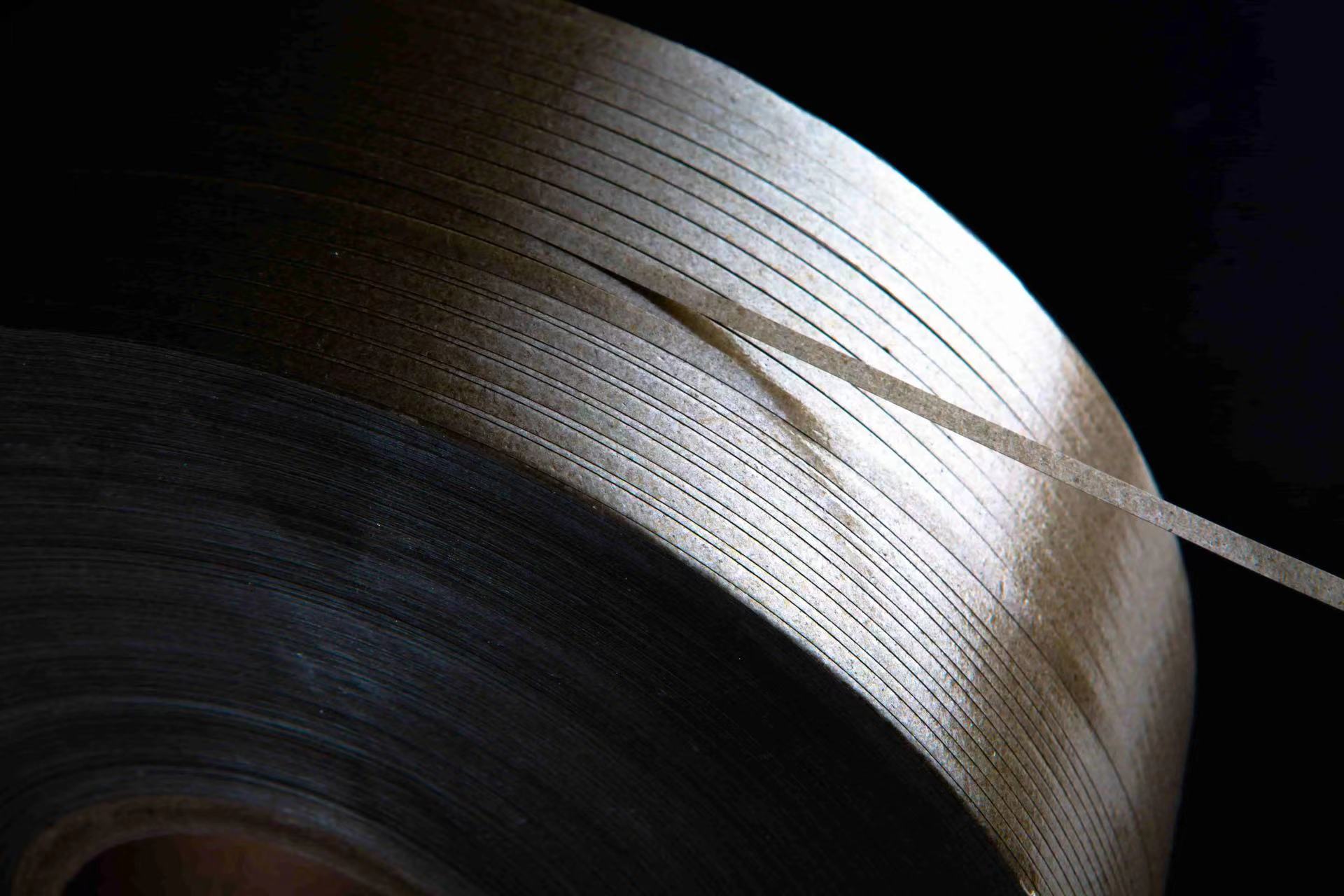

The use of mica tape

Mica tape is actually a very good insulation material. It has excellent fire resistance, so it is basically used in insulation and fire-resistant materials. Just like the commonly used cables, in some special environments, the requirements for cables are relatively high, they need to be fire-resistant and high-temperature-resistant, and mica tape will be added to the cable as insulation material.

In addition, in some high-quality motors, mica tape is also used mainly because of its insulation and high-temperature resistance properties. When using mica tape, it must be closely attached to the wire, that is, the stator winding of the motor, to avoid damage caused by the friction between mica tapes due to the high-speed operation of the motor.

The production process of mica tape

The manufacturing method of mica tape can be divided into wet method and dry method. The wet method refers to the asphalt mica tape bonded with asphalt without drying, with a volatile content of more than 6%. This method has been eliminated. The dry method is to bond the reinforcing material, thin mica or powdery mica paper with adhesive, and then bake it to obtain mica tape-shaped material.

Stick the mica tape on the sheet mica tape sticking machine. Generally, the mica sheets are manually pasted in a fish-scale order on the lower reinforcing material, and then compounded with the upper reinforcing material coated with glue. When reaching a certain size, unload the coil, cut the board, and pack. In the production process, the control of the glue content of the mica tape is very important. When the speed is constant, the glue amount is controlled by controlling the viscosity and solid content of the glue.

The production of powdery mica tape is carried out on the powdery mica tape lamination machine (most of the multi-gel system mica tapes use calcined powdery mica paper, called mature paper or raw paper), first put on the reinforcing material, drive up the glue, and then put it into the oven for drying, then collect the coil, cut the adhesive tape, and pack.

When the powdery mica tape is dried, sufficient time should be given to remove the organic solvent, so that the resin is in a semi-cured state to ensure that the mica tape is easy to untie, does not bubble, and does not become hard. The oven temperature of various epoxy powder mica tapes is divided into three stages: the inlet temperature is low, generally around 80-100℃, to prevent a large amount of solvent volatilization and cause powdery mica paper to bubble; the middle temperature is controlled at 120-160℃; the rear temperature is controlled at 110-150℃.

To ensure that the mica tape has good flexibility and manufacturability, in addition to controlling the drying temperature and speed, it is necessary to control the gel time of the mica tape glue, so that the gel time is stable within a small range.