Composition of mica products

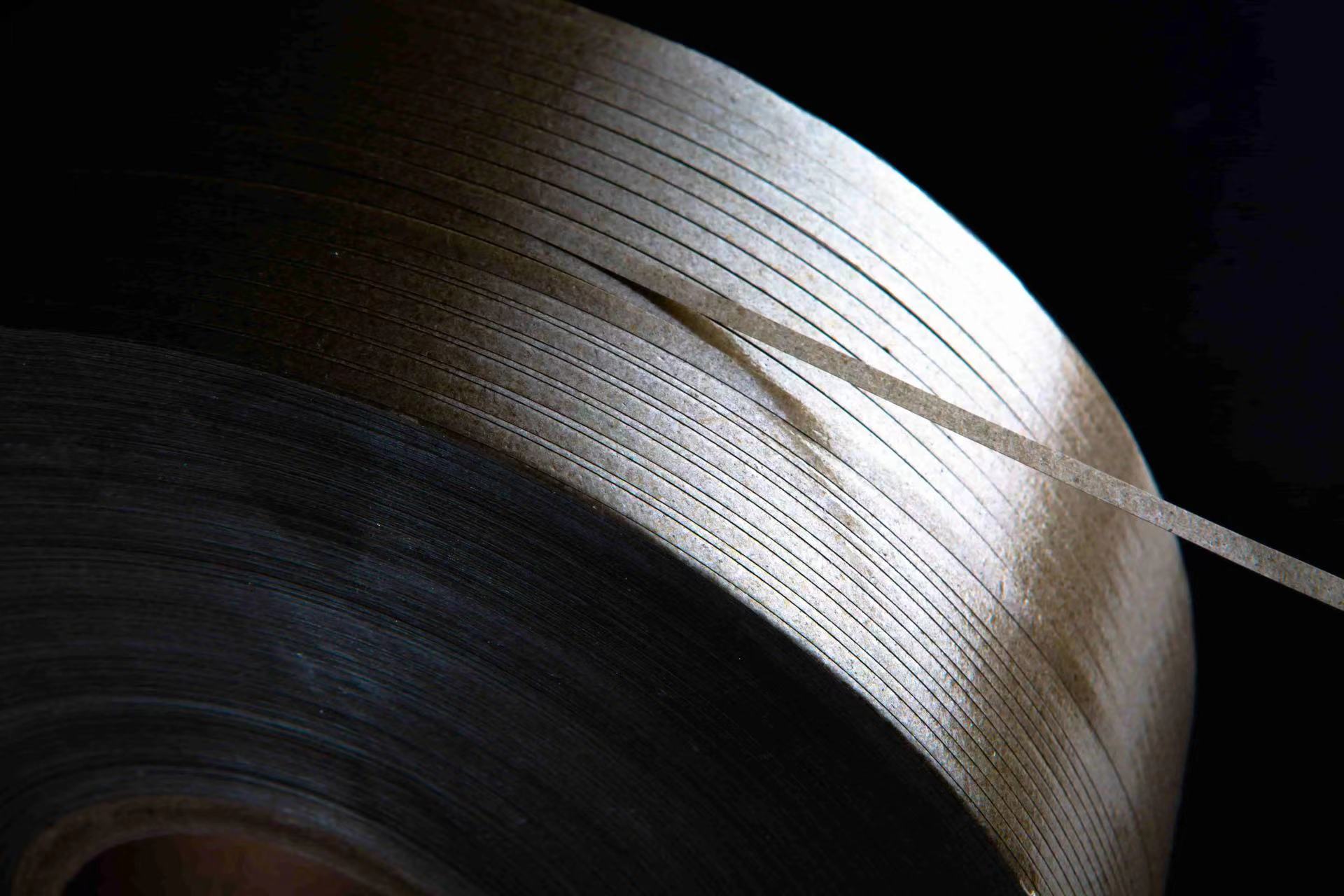

Mica products mainly include mica tape, mica sheet, mica foil, etc., which are composed of mica or mica powder, adhesive, and reinforcing materials. Different material combinations can be used to produce mica insulation materials with various properties. Mica tape is composed of adhesive, mica powder, or sheet mica, and reinforcing materials. It is mainly used for high-voltage motor main insulation or interphase insulation. Soft mica sheets are divided into two categories: soft mica sheets and mica foils. Soft mica sheets are mainly used for motor slot insulation and end layer insulation.

Mica foil has B-grade corona-resistant glass mica foil (5833) with a dielectric strength of 16-35kV/mm; B-grade epoxy glass powder mica foil (5836-1) with a dielectric strength of 16-35kV/mm; H-grade silicone glass mica foil (5850) with a dielectric strength of 16-35kV/mm; F-grade polyimide film glass powder mica foil with a dielectric strength of 40kV/mm.

Mica is a kind of rock-forming mineral, usually presenting a pseudohexagonal or diamond-shaped plate, flake, or columnar crystal shape. The color varies with changes in chemical composition and mainly deepens with increasing Fe content. The most commonly used in the industry is white mica, followed by gold mica. It is widely used in the building materials industry, fire protection industry, fire extinguishing agents, welding rods, plastics, electrical insulation, papermaking, asphalt paper, rubber, pearlescent pigments, and other chemical industries.

Mica products’ adhesives mainly include asphalt paint, corona-resistant paint, alkyd acid paint, epoxy resin paint, organosilicon paint, and ammonium phosphate solution. Reinforcing materials mainly include mica tape paper, silk, and alkali-free glass cloth.

Mica tape is an insulating material in a band shape that is formed by bonding mica flakes or mica powder paper with adhesive and reinforcing materials, then dried and cut. Mica tape is flexible at room temperature and can be wrapped around motor wires with good mechanical and electrical properties in cold and hot conditions, and good corona resistance.

What are the uses of different mica products?

There are many insulation products made of mica, mainly including the following:

- Soft mica sheet. Soft mica sheets are relatively soft at room temperature and can bend. They are mainly used for motor slot insulation, inter-turn insulation, and interphase insulation.

- Shaped mica sheet. Shaped mica sheets are relatively hard at room temperature, and can be softened by heating and then molded into various shapes of insulating parts. They are mainly used to make V-shaped rings for DC motor commutators and other insulation parts.

- Mica tape is relatively soft at room temperature and is suitable for motor and electrical wire coil and connection wire insulation.

- Commutator mica plate. Commutator mica plates contain less adhesive, are very hard at room temperature, and have even thickness. They are mainly used for inter-layer insulation of DC motor commutators.

- Pad mica sheet. Pad mica sheets are suitable for making insulation pads for motor and electrical appliances.