What is a mica sheet level gauge?

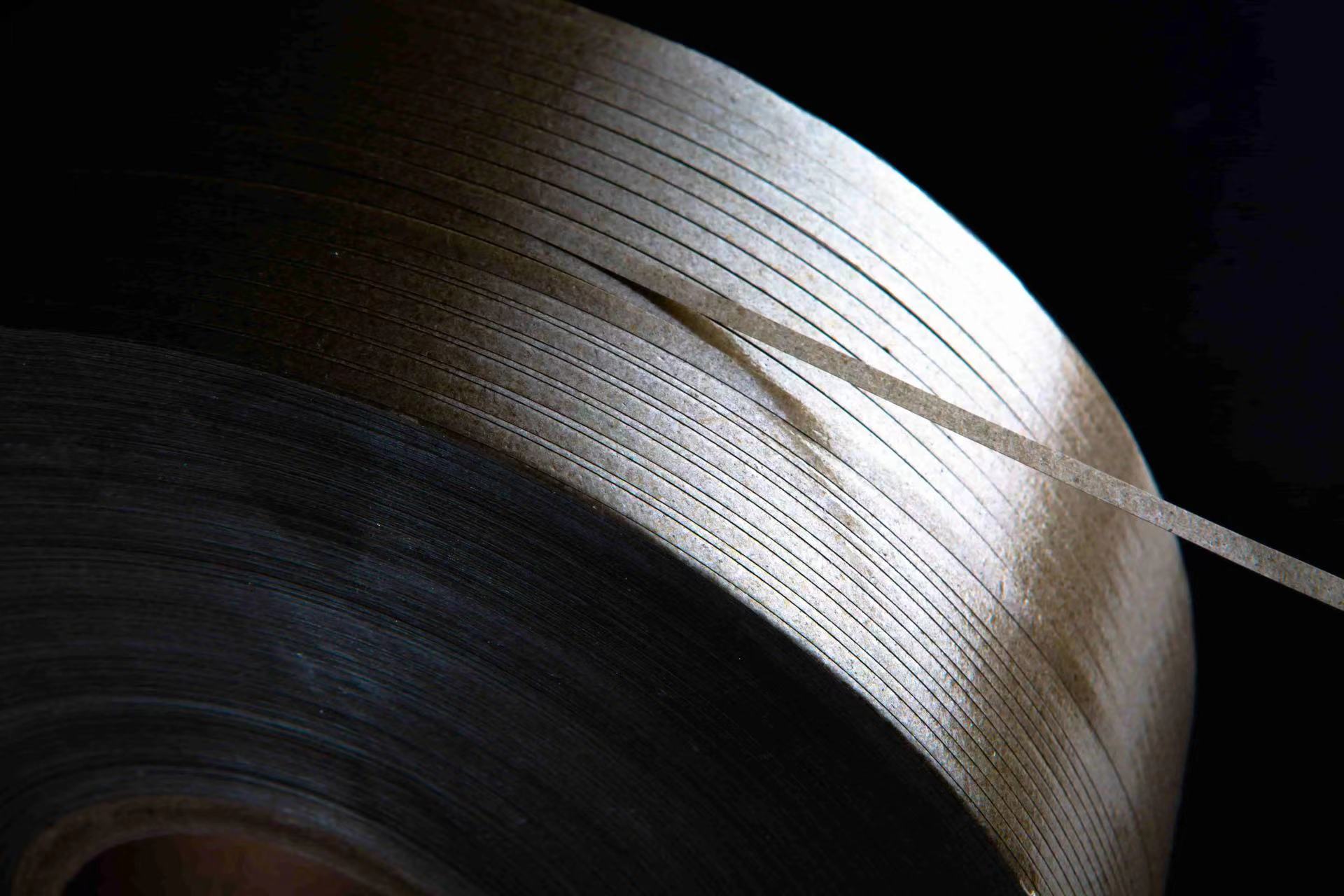

A mica sheet level gauge is composed of the main body, seal gasket, anticorrosion gasket, protective gasket, protective tape, plane mirror, buffer gasket, pressure cover, bolt, washer, nut, etc.

The light emitted by the red and green light source is projected into the liquid cavity of the level gauge. In the vapor phase part of the cavity, the red light is projected directly forward, while the green light is absorbed by the wall after being projected obliquely. In the liquid phase part of the cavity, due to the refraction of the water level, the green light is projected directly forward, while the red light is projected obliquely on the wall. Therefore, when viewed directly ahead, it displays red gas and green water.

What requirements must be met for the mica sheet level gauge?

- The dimensional tolerance limit must comply with regulations.

- Synthetic mica sheets are colorless and transparent, and natural mica sheets can be light-colored and transparent.

- The product is not allowed to have cracks, perforations, concave angles, inclusions, etc.

- The product surface requirements are flat, clean, free of oil stains, hard texture, and without obvious wrinkles.

- The requirements for edge layering, edge cracks, external burrs, sheet thickness, and internal burrs must be within the specified range.

- If the thickness is uneven, it must not be greater than 0.02mm.

What should be noted when replacing the mica sheet level gauge?

- Prepare the corresponding components in advance, check whether they are intact, and prepare the tools.

- The operator should dress neatly, stand on the other end of the pressure cover, and start to loosen the bolts on the other side with the tools. The side close to the body can only be disassembled after confirming that there is no pressure and no gas.

- Take off the components, clean the bonding surfaces, and apply lead powder on the bolts.

- Install the seal gasket, anticorrosion gasket, protective gasket, protective tape, plane mirror, and buffer gasket correctly. When tightening the bolts, tighten them evenly several times to ensure that the force is even.

- Within the range of 6mm from the edge, a small amount of spots, bubbles, and slight wrinkles are allowed to exist in the protective layer, but there must be no fluff, delamination, or serious blockage. Within the usage area, slight knife marks, red-green silk are allowed to exist, but there must be no bubbles or any shaped spots.

DataMica has more than 30 years of experience in mica product processing. We are experienced in manufacturing ultra-thin mica paper, reinforced mica paper, 3D mica laminated board, gold mica ceramic tape, and more mica-based specialty products. Our core value product is the HiResist mica product used for battery thermal runaway protection. Since 1992, our vision, expertise, and focus on customer satisfaction has made us a powerful competitor in the high-temperature insulation industry. Welcome to inquire.